Frank WInfield Woolworth was born on the 13th of april 1852. The F. W. Woolworth Company (often referred to as Woolworth) was a retail company and one of the pioneers of the five-and-dime store. It was among the most successful American and international five-and-dime businesses, setting trends and creating the modern retail model that stores (regretfully) follow worldwide today.

FW Woolworth once said: ‘I am the world’s worst salesman, therefore, I must make it easy for people to buy’.

Ironically, he wasn’t exactly tightfisted when he decided to build his own skyscraper.

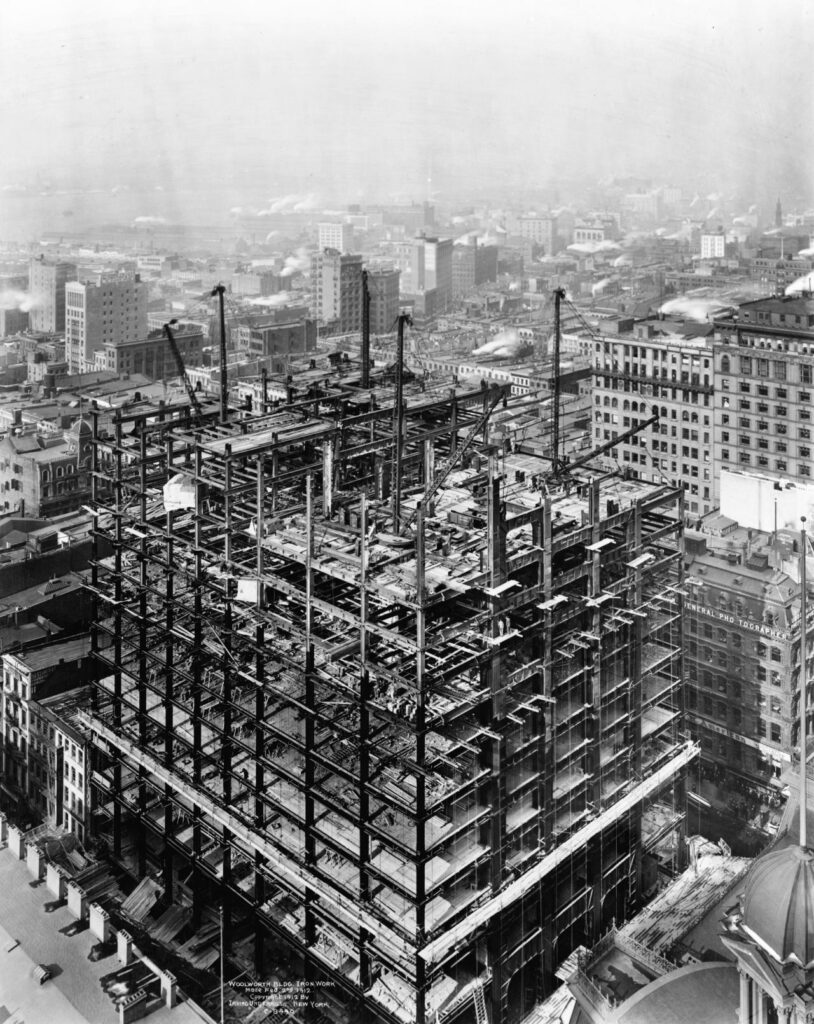

When the neo-Gothic Woolworth Building at 233 Broadway was erected in 1913 as the world’s tallest building, it cost a total of $13.5 million to construct (equivalent to $353 million today). Though many have surpassed it in height, the instantly-recognizable Lower Manhattan landmark has remained one of the world’s most iconic buildings, admired for its terra cotta facade and detailed ornamentation, and its representation of the ambitious era in which it arose.

Photo: Irving Underhill

The architect Cass Gilbert utilized the most advanced steel-frame construction techniques of the time allowing the Woolworth to soar 57 stories to 241m. For the wind bracing, the entire Woolworth Building was considered as a vertical cantilever, and correspondingly large girders and columns were used in the construction.

Photo: ©www.6sqft.com

Continuous portal bracing was used between the 1st and 28th floors, except in the interior columns, where triangular bracing was used. The portal braces on the building’s exterior direct crosswinds downward toward the ground, rather than into the building.Interconnecting trusses were placed at five-floor intervals between the tower and the wings; these, as well as the side and court walls, provided the bracing for the wings.

Image courtesy of Shutterstock

Above the 28th floor, knee braces and column-girder connections were used; hollow-tile floors were installed because it would have taken too long to set the concrete floors, especially during cold weather. The two basement levels used reinforced concrete. Exactly what concrete is good at (i couldn’t resist).

About the Author:

Bruno Dursin – Managing Director at Believe in Steel. Bruno has more than 30 years of experience in promoting steel & steel solutions. His clients benefit from his extensive network within the building industry.