Sir Henry Bessemer (19 January 1813 – 15 March 1898) was an English inventor, whose steel-making process would become the most important technique for making steel in the nineteenth century for almost one hundred years from 1856 to 1950.

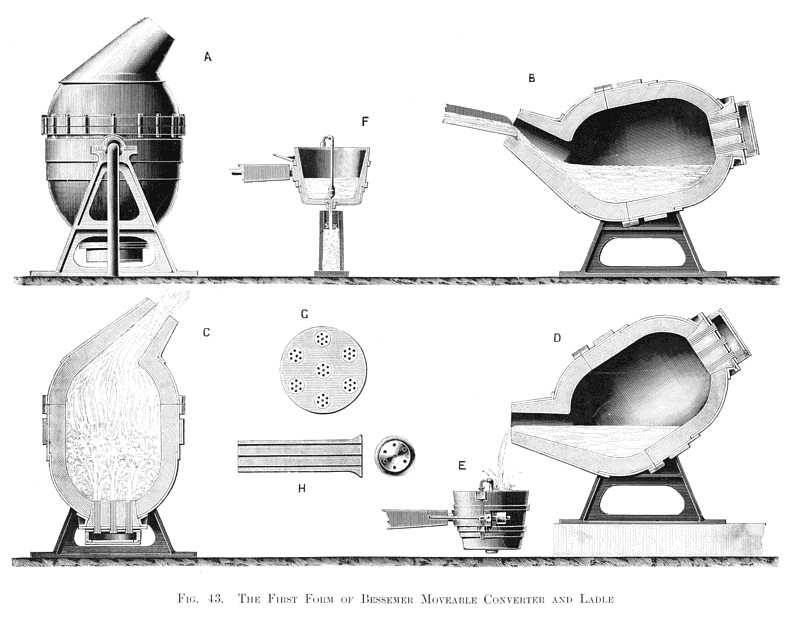

Bessemer had been trying to reduce the cost of steel-making, and developed his system for blowing air through molten pig iron to remove the impurities. This made steel easier, quicker and cheaper to manufacture, and revolutionized structural engineering.

Photo: cooldudeandy01

Many industries were constrained by the lack of steel, being reliant on cast iron and wrought iron alone. Examples include railway structures such as bridges and tracks, where the treacherous nature of cast iron was keenly felt by many engineers and designers.

There had been many accidents when cast iron beams collapsed suddenly, such as the Dee Bridge disaster of May 1847 and failures continued until all cast iron under-bridges were replaced by steel structures.

Photo: Public Domain

Though this process is no longer commercially used, at the time of its invention it was of enormous industrial importance because it lowered the cost of production steel, leading to steel being widely substituted for cast iron and wrought iron.

Bessemer licensed the patent for his process to five ironmasters, but from the outset, the companies had great difficulty producing good-quality steel. The breakthrough came when Robert Forester Mushet a technique allowing the quantity of carbon to be controlled by removing almost all of it from the iron and then adding an exact amount of carbon and manganese, in the form of spiegeleisen. This improved the quality of the finished product and increased its malleability.

About the Author:

Bruno Dursin – Managing Director at Believe in Steel. Bruno has more than 30 years of experience in promoting steel & steel solutions. His clients benefit from his extensive network within the building industry.