Inauguration of the Forth Bridge.

The Forth Bridge is a cantilever railway bridge across the Firth of Forth in the east of Scotland, 9 miles (14 km) west of central Edinburgh. Completed in 1890, it is considered a symbol of Scotland and a UNESCO World Heritage Site. It was designed by English engineers Sir John Fowler and Sir Benjamin Baker.

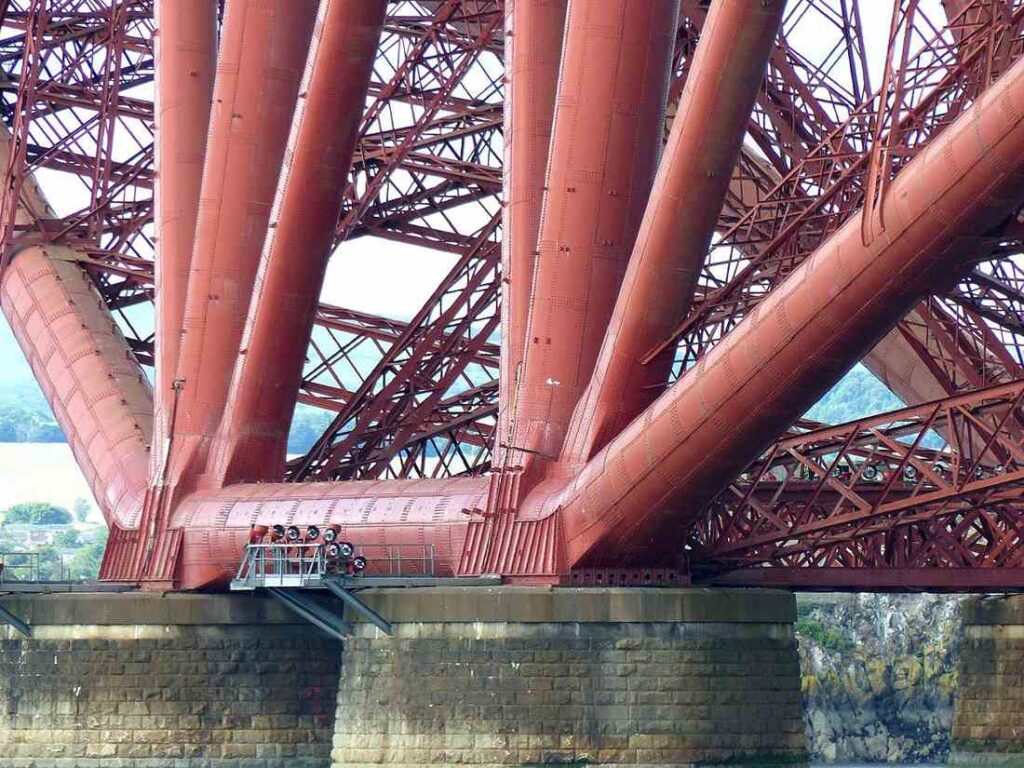

Photo: MrMasterKeyboard

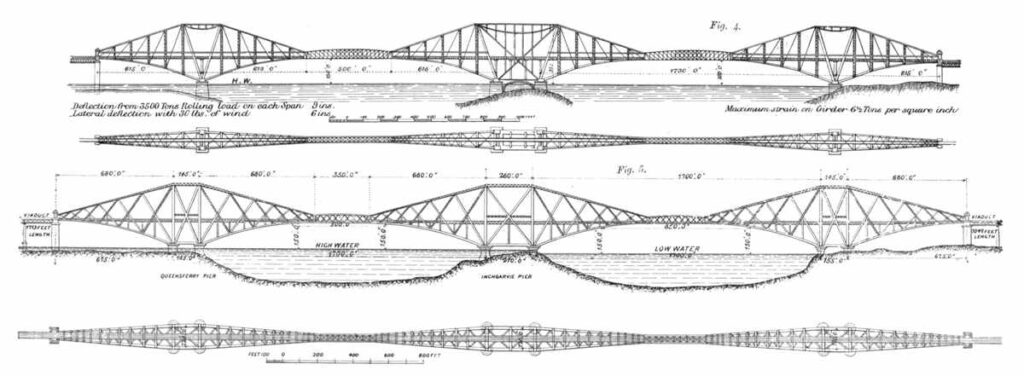

Construction of the bridge began in 1882 and it was opened on 4 March 1890 by the future Edward VII. The bridge has a total length of 2.467 m. When it opened it had the longest single cantilever bridge span in the world, until 1919 when the Quebec Bridge in Canada was completed.

The bridge consists of three huge double cantilever sections connected by trusses forming two central spans of 521 m. The upper and lower trusses are made of steel and dissipate forces to the granite piers with iron caissons. The anchor arms have a counterweight of 1.000 tons.

Photo: Adrian Pingstone / Public Domain

It was the first major bridge built mainly of steel. Approx. 4.000 workers were employed every day to build the bridge and 6.5 million rivets and 65.000 tons of steel were used. It would take three Eiffel Towers to span the same distance as that of the triple cantilever sections of the Forth Rail Bridge. The bridge is considered the “largest structure of the 19th century”. The three cantilever structures are 110 m high.

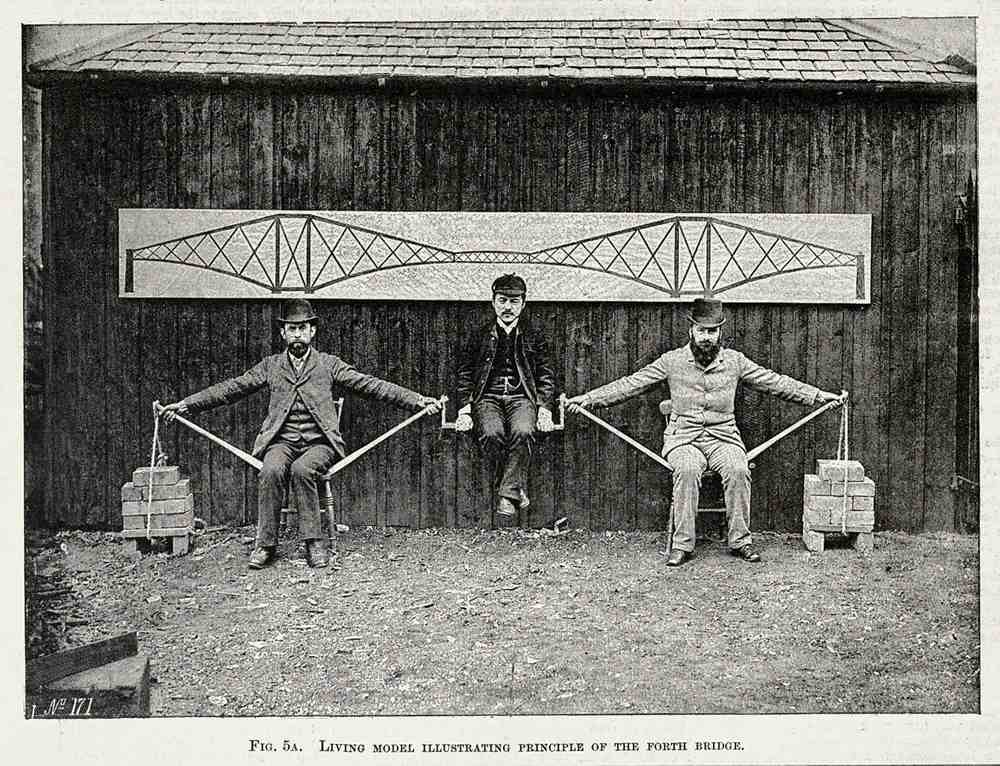

Photo: Harvey Henkelmann

To illustrate the cantilever structure, a demonstration with people was given. The load is represented by the figure sitting on the suspended span in the middle. The arms of the figures on the sides symbolize the tension in the connecting beams. The wooden struts symbolize the pressure in the lower sections. The bricks represent the anchor points in the pylons.

Building the cantilevers.

Photo: Public Domain

The tubular members were constructed in a workshop at South Queensferry. To bend plates into the required shape, they were first heated in a gas furnace, and then pressed into the correct curve.

Photo: Public Domain

The curved plates were then assembled on a mandrel, and holes drilled for rivets, before they were marked individually and moved to the correct location to be added to the structure. Lattice members and other parts were also assembled at South Queensferry, using cranes and highly efficient hydraulic rivetters.

About the Author:

Bruno Dursin – Managing Director at Believe in Steel. Bruno has more than 30 years of experience in promoting steel & steel solutions. His clients benefit from his extensive network within the building industry.