Werner Sobek was born 1953 in Aalen, Germany. From 1974 to 1980, he studied structural engineering and architecture at the University of Stuttgart. In 1992 he founded his own company. Werner Sobek which now has offices in Stuttgart, Frankfurt, London, Moscow, New York, and Dubai. Its core areas of expertise are lightweight construction, high-rise construction, façade design, special constructions made from steel, glass, titanium, fabric and wood, as well as the design of sustainable buildings. His commitment to sustainability is also reflected in his involvement in the German Sustainable Building Council, which he co-founded in 2007.

Werner Sobek is known for his environmentally sustainable and self-sufficient prototype houses such as R 128 and H16.

© Roland Halbe

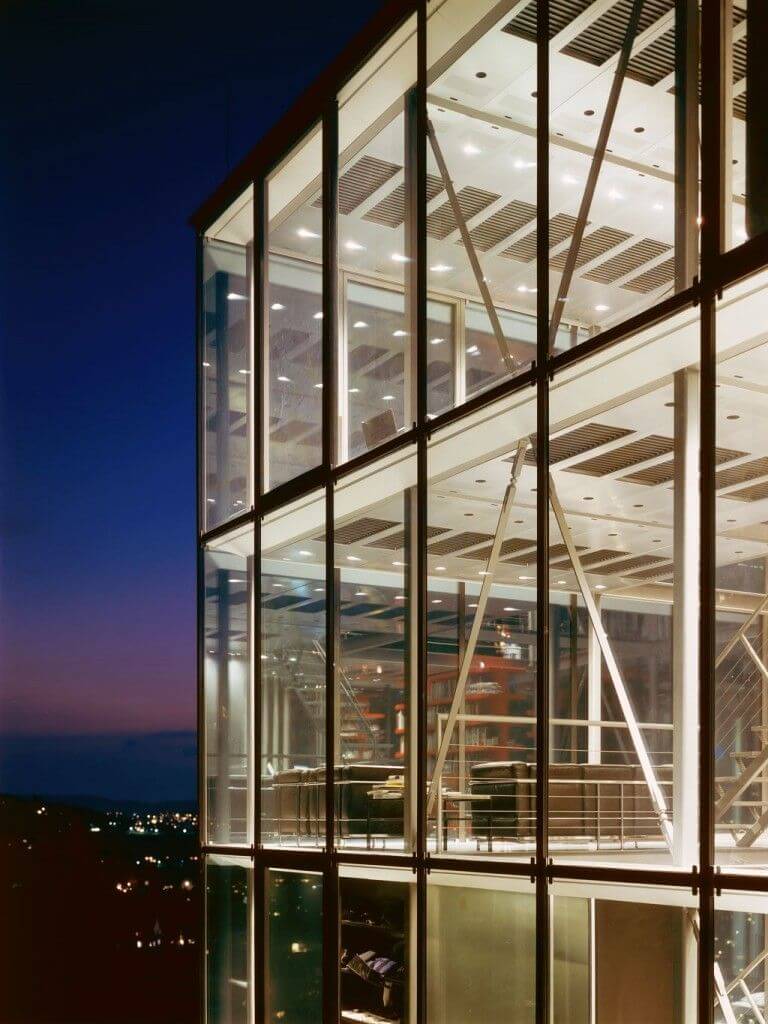

House R 128 features a modular and recyclable design, is completely glazed and has no interior dividing walls.. Owing to its passive solar architecture with triple-glazed walls, the house needs no energy for heating. Electricity is generated by solar cells.

© Roland Halbe

The structural frame of the house consists of a bolted steel skeleton with four floors spaced on 2.8 m centers. The total height of the building is 11.2 m. Twelve support columns are arranged on a plan grid spaced at 3.85 x 2.90 m and linked by rails in two directions. At the nodal points the square hollow column sections are interrupted by solid steel pieces whose sharp corners provide a precise fit for the rails. The frame is stiffened vertically on three sides by diagonal tensile braces.

© Roland Halbe

Horizontally the floors are also stiffened by diagonal tensile braces. Columns and beams were bolted together on site. The bolts were screwed into the threaded holes in the columns; no nuts were used. The precision of the prefabricated components eliminated any necessity for tolerance-compensating measures. The four-storey steel frame, which is still visible in the completed building, was fully assembled in four working days.

© Roland Halbe

About the Author:

Bruno Dursin – Managing Director at Believe in Steel. Bruno has more than 30 years of experience in promoting steel & steel solutions. His clients benefit from his extensive network within the building industry.