Thermal bridging is a critical challenge in building design, occurring when a conductive material penetrates a building’s insulated envelope. This process creates pathways for heat transfer, undermining the energy efficiency and comfort of the structure. Solutions like structural thermal breaks address these challenges while offering additional benefits for engineers and building occupants alike.

Understanding Thermal Bridging and Structural Thermal Breaks

Thermal bridging happens when building elements like balconies, exposed slab edges, or rooftop connections disrupt the insulation layer, allowing heat to escape. Left unaddressed, this phenomenon can lead to significant energy loss, colder interior surfaces, and even condensation issues that compromise structural integrity.

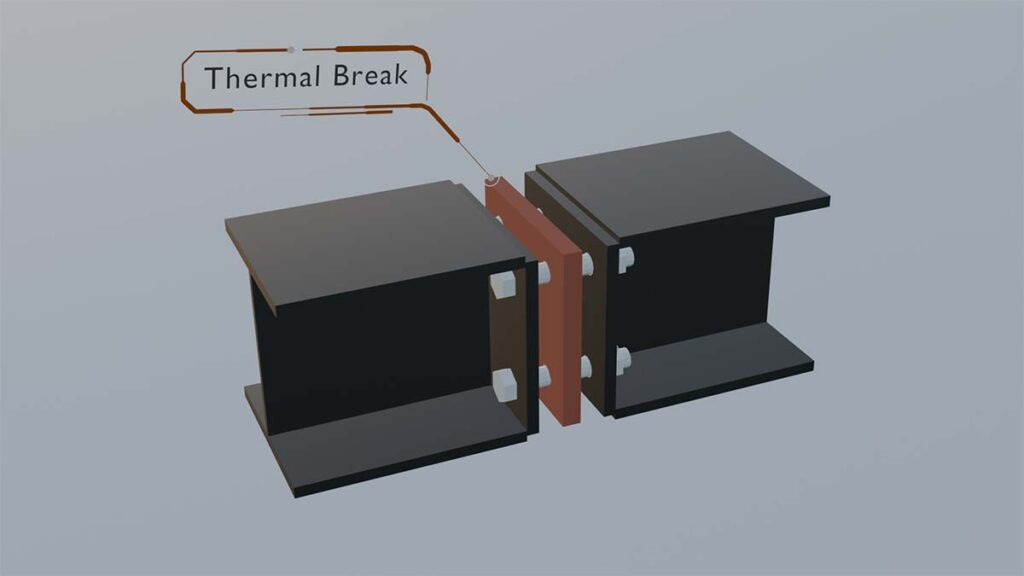

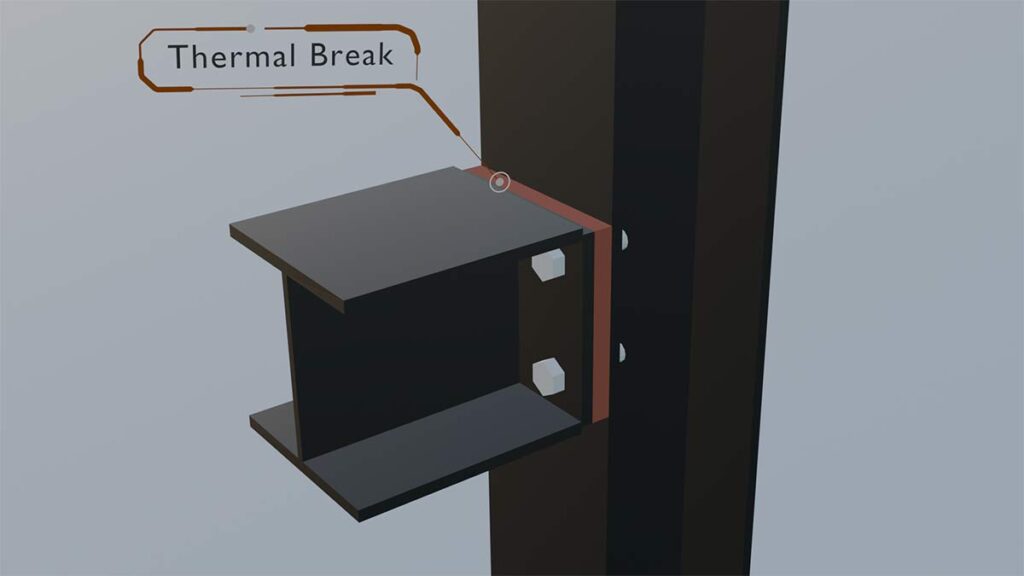

Structural thermal breaks are innovative solutions designed to interrupt these thermal bridges. Positioned at the points of penetration, such as between a building’s interior slab and exterior balcony, they reduce heat transfer while maintaining structural integrity. For instance, these components transfer structural loads—such as those from an exterior balcony—back to the building’s interior, all while preserving the insulation envelope.

Benefits of Structural Thermal Breaks

The advantages of structural thermal breaks extend beyond energy savings:

- Energy Efficiency: By minimizing heat transfer, these components significantly reduce energy consumption and heating costs.

- Thermal Comfort: Structural thermal breaks help maintain consistent interior temperatures by preventing cold surfaces from forming inside. This ensures a more comfortable environment for occupants, especially in colder climates.

- Condensation Prevention: One of the most critical benefits is reducing the risk of condensation. By preventing interior surfaces from reaching the dew point, structural thermal breaks protect against mold growth and structural degradation caused by trapped moisture behind facade components.

Types of Structural Thermal Breaks

Structural thermal breaks come in various forms to suit different applications:

- Balcony Connections: These are often modular systems designed for concrete balconies, enabling load transfer while maintaining thermal insulation.

- Steel Modules: Used for higher structural demands, these modules balance strength and insulation, particularly in steel-to-concrete or steel-to-steel connections.

- Facade and Roof Connections: Designed for applications like rooftop equipment or facade components, these breaks ensure continuity in the insulation layer.

Each type is carefully engineered to balance structural needs with thermal performance, often incorporating high-performance materials like stainless steel for durability and low thermal conductivity.

Design Considerations for Engineers

When incorporating structural thermal breaks into a project, engineers must navigate several key considerations:

- Load Distribution: Engineers must calculate and ensure that the break can transfer structural loads effectively while maintaining the thermal barrier.

- Slab Stiffness: For concrete applications, the interior slab must be adequately stiff to support the exterior loads transmitted through the thermal break.

- Customization: Components such as rebar and insulation thickness can be tailored to meet specific project requirements, ensuring compatibility with both the thermal and structural design goals.

Manufacturers often provide software tools and detailed technical support to assist engineers in integrating these systems seamlessly into their designs.

Are Structural Thermal Breaks Required by Building Codes?

Building codes increasingly recognize the importance of addressing thermal bridging. In cities like New York and Seattle, structural thermal breaks are now mandatory for certain applications, such as balcony connections. On a broader scale, standards like ASHRAE 90.1 include provisions for mitigating thermal bridging, though enforcement varies by jurisdiction.

In colder climates, where the risk of energy loss and condensation is higher, building codes are more likely to require these solutions. As awareness of energy efficiency and sustainability grows, it’s anticipated that more regions will incorporate thermal bridging mitigation into their regulations.

Who Designs Structural Thermal Break Connections?

The responsibility for designing structural thermal break connections typically lies with structural engineers, often in collaboration with product manufacturers. Engineers assess the structural loads and recommend appropriate solutions, while manufacturers provide technical guidance and product specifications.

By integrating thermal breaks during the design phase, engineers can avoid delays and additional costs associated with late-stage design revisions. This collaborative approach ensures both the structural integrity and thermal performance of the building.

Conclusion

For engineers, integrating structural thermal breaks requires a balance of technical expertise and collaboration with manufacturers to ensure both thermal and structural objectives are met. As building codes evolve to emphasize energy efficiency, the use of thermal breaks is set to become a standard practice in many regions, particularly in colder climates.

Engineers should remain curious, embrace learning opportunities, and don’t shy away from exploring niche fields within engineering. These experiences can lead to meaningful contributions to a more sustainable and innovative built environment.