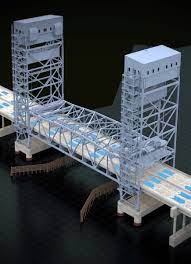

The immaculate Gilmerton Bridge, which was originally a twin drawbridge completed in 1938, is now a state-of-the-art vertical-lift bridge. This stunning piece of architecture spans the Southern Branch of the Elizabeth River in Chesapeake, Virginia. Part of the Military Highway, it carries US Route 13, as well as US 460. The $134 million replacement project began in November of 2009 and was estimated to take four years to complete. This massive project was finally completed in October of 2013 and is still owned, operated, and maintained by the City of Chesapeake.

Source: change.org

Source: bridgehunter.com

The Purpose of the Replacement Project

The main purpose of the replacement project was to increase the vertical clearance of the life bridge, which allows much larger vessels to travel safely underneath the bridge. In turn, this reduces the sheer number of bridge lifts required throughout the day and thus, allows for a smoother ebb and flow of traffic – creating a greater reduction of congestion and time delays. The project also allows for wider land widths, which helps to accommodate the future expansion of Route 13 and the Military Highway as it moves from four lanes to six.

Source: cityofchesapeake.net

Source: flickr.com

The Architecture and Dimensions of Gilmerton Bridge

The new four-lane vertical-lift bridge is comprised of a single span and rises vertically while remaining parallel with the bridge deck. This accommodates any maritime traffic and then descends smoothly to close. The total lift span length of the new bridge is 250 ft., with the open position measuring 135 ft. and the closed position measuring 35ft. The bridge width itself is 85 ft., which certainly leaves room for the future expansion of the adjacent highway. The astounding vertical lift towers measure a height of 207 ft., each including 1,009 steel members. These steel members weigh approximately 5,000 to 150,000 pounds apiece.

Source: bridgehunter.com

Source: bridgehunter.com

Structural Concept and Design Facts

As the purpose of this building was to assist in both maritime and vehicular traffic, this bridge was built with an outstanding structural concept. The bridge required eight 12 ft. diameter drilled shafts, which are among the largest that have ever been constructed in US history. They were constructed using the oscillator method with the assistance of temporary casing methods. This project involved 10 million pounds of structural steel and 3.1 million pounds of reinforcing steel. In addition, construction required 30,000 cubic yards of concrete, 7,000 yards of structural fill, and 4,500 linear feet of drainage pipe. The bridge consists of four 15 ft. high retaining walls, eight 15 ft. diameter sheaves, and required 200 different assembly lots of bolts.

Source: roushcivil.com

Architect and Structural Engineer Information

The replacement project and bridge construction was entirely overseen by the Virginia Department of Transportation (VDOT). However, as this project required a mass amount of resources and manpower, there was a large team involved. In terms of an Engineer of Record, this included both Modjeski and Masters for moveable bridges and Gannet Flemming for approach bridges. As for the General Contractor, this was handled by PCL Civil Constructors, as well as Major Subcontractors like EV Williams Inc., McLean Contracting, DT Read, and Edwards Electric.

Source: modjeski.com

Source: modjeski.com

Interesting Facts About the Phased Construction and Challenges Faced

As this project was a major undertaking and there were many complexities associated with it, the construction of the bridge occurred in stages. The initial stage of construction involved shifting the existing four-lane traffic into two-lane traffic. This included the construction of two southbound lanes, the lift span, and the bridge towers. This was also when the installation of the mechanical and electrical lift span occurred. The second phase of construction included the installation of the float-in lift span, as well as the further shifting of traffic to the new bridge to the two south-side lanes. The final stage of construction involved the demolition of the existing bridge, the reconstruction of the two northbound lanes, and lastly, the eventual reopening of all four travel lanes.

Considering the four-year benchmark for the completion of the reconstruction project, there were some significant obstacles and challenges that were faced. The first issue was that there was limited access between the railway and the existing bridge, which meant there was an abundance of coordination required with the Norfolk Southern Railway. Other challenges were the necessity for the tower erection to occur over the existing railway, the building of the new bridge both over and under the existing bridge, as well as the demolition of the existing bridge under the newly constructed one. This meant that the bridge needed to be closed each night after 8 pm and would not reopen until the following morning at 5 am. The reconstruction project also meant that there would be restricted channel closures for all maritime traffic.

Source: flickr.com

Conclusion

In conclusion, the Gilmerton Bridge project was incredibly challenging and time-consuming. However, it was a necessity. The lift bridge now allows for a smoother transition of both vehicular and maritime traffic. It also allows for the future expansion of the Military Highway and Route 13. Because of this, this architectural marvel has greatly improved the Chesapeake area.