What is Chevron Bracing?

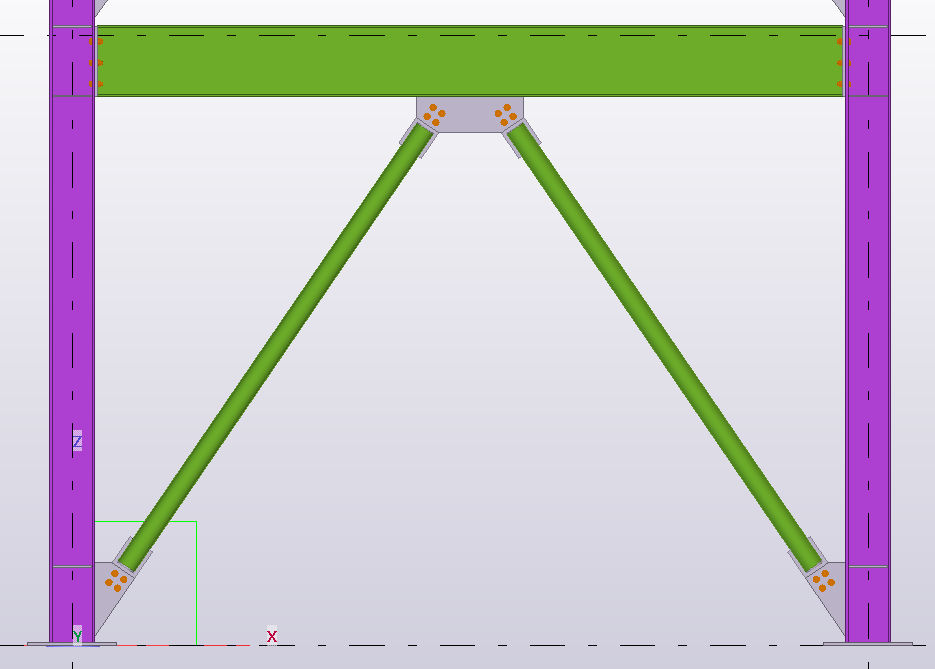

In steel-framed buildings, chevron braces are a common arrangement for providing lateral-load resistance. Chevron bracing uses two members connecting at a central point on the upper horizontal to form an inverted V. The bare frame is connected with 5 points in this form of connection. For lateral force resistance against gravity, wind, and low-seismic loads, chevron bracing is an excellent choice. There are exceptions to these general rules of thumb, but they should be sufficient for the preliminary design of braces and connections or cost estimation.

Purpose of Chevron Bracing

Some of the purposes of Chevron Bracing are:

- These are widely used to resist earthquake and wind stresses as effective lateral load resisting devices.

- Chevron bracing is applied for architectural openings like doors, windows, mechanical openings, and elevators. Due to post-buckling compressive strength deterioration and full yielding of the braces, existing standards for chevron bracing require beams of chevron bracing to resist significant vertical and axial demands due to imbalanced brace forces. When using chevron bracing, it is necessary to use massive beams to support the braces.

- Chevron bracing can be used to create openings between the braces. In contrast, some architects prefer to place the braced frame on the structure’s exterior, while others prefer to place it in the building’s internal core.

- It is also possible to restrict the overall deformation capacity of chevron bracing by limiting the beam response to elastic behaviour.

Components of Chevron Bracing

Chevron Bracing is made up of two members that meet in the middle of the upper horizontal member. This system can reduce the compression brace’s ability to buckle so much that it is less than the tension brace’s ability to yield under tension. This can mean that when the braces reach their limit, the load must be stopped by stopping the horizontal member from bending.

For a feasible range of unfactored brace forces, estimated brace sizes, gusset plate thicknesses, and bolt or weld size and length requirements are provided. The brace is attached to the gusset plate using bolts and welds. For each of the four varieties of chevron bracing, which are HSS, W-shapes, WT shapes, and double angles, there are suggested specifics for the various connections. If you are welding a gusset to a round or square piece of HSS, you will need welds at least 1.3 times their diameter.

Conclusion

According to new research, code requirements for chevron-shaped buildings with concentric braces are not always successful at keeping nondissipative elements from yielding or buckling. They don’t always provide collapse mechanisms that cause uniform damage to the braces. As a result, additional investigation is required.